New product generation

Since its beginnings in the 1970s, Inpro has been known for manufacturing reliable and robust transfer units. In response to the constantly evolving needs of the market, now in 2024, Inpro is introducing our new generation of Inpro NEXT products, taking a leap to the next level.

What is Inpro NEXT?

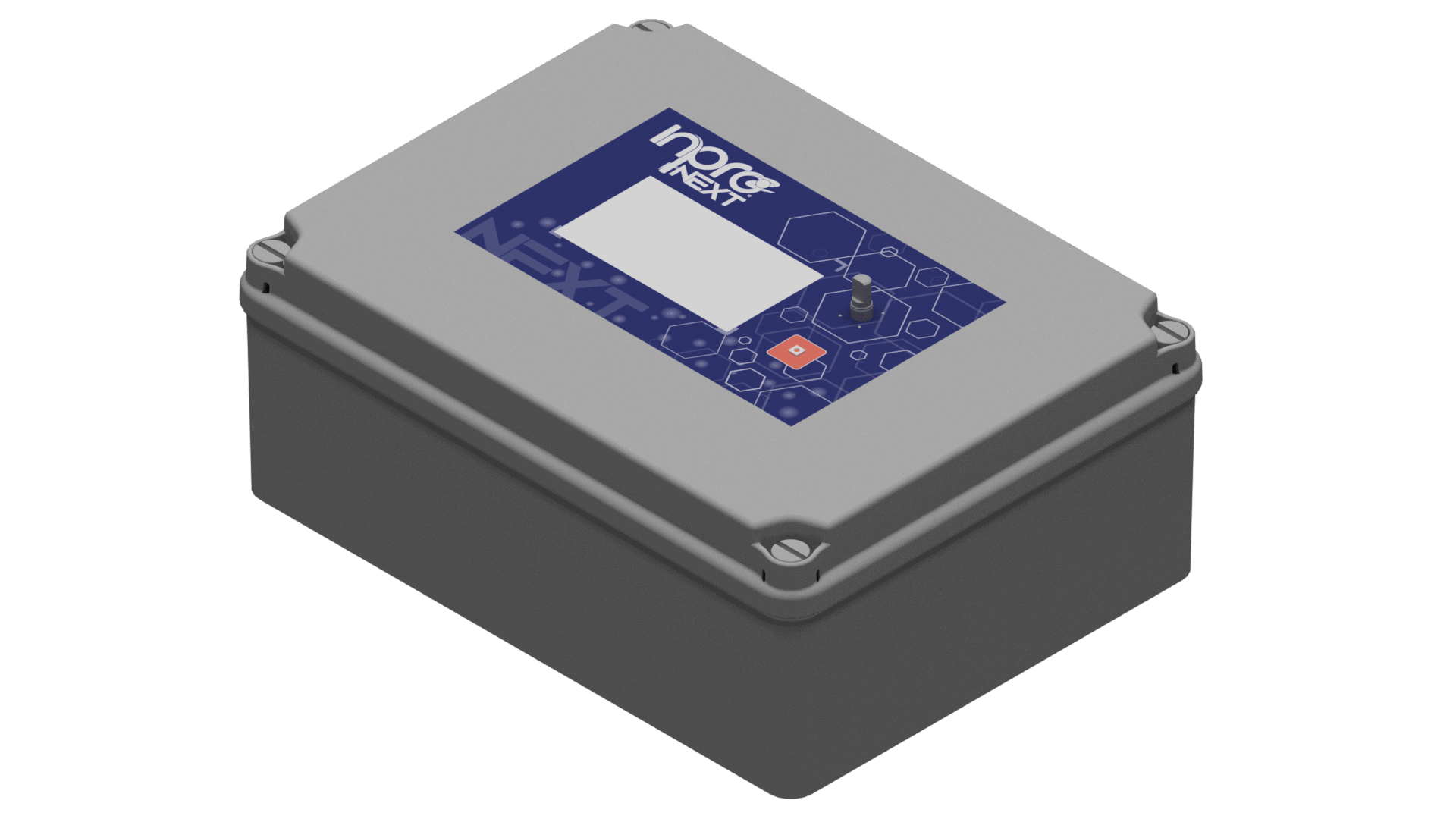

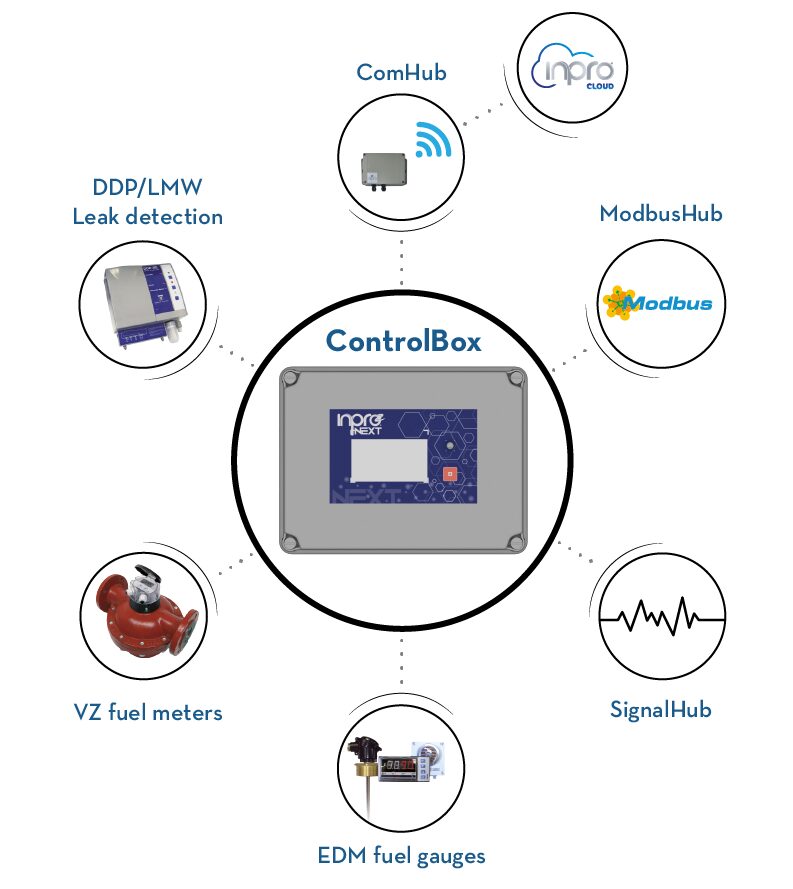

Inpro NEXT is the new product range, which maintains the essence of Inpro’s traditional products, but with new technical characteristics, whose central axis is the ControlBox: a unified control that provides Connectivity, Modularity, Versatility and Sustainability, allowing a reduction in the number of references, as we unify our equipment.

This generation of units has become more attractive with new features and a number of advantages.

Therefore, in every project we will save resources and simplify every commissioning of our equipment.

With Inpro NEXT we are taking the quality and innovation of our products to the next level, offering our customers more productive, flexible and more sustainable equipment.

With Inpro NEXT we maintain our commitment to continue with the same projects offering units that includes a ControlBox, interactive screen and with the extra possibility of connectivity.

Main features

CONNECTIVITY

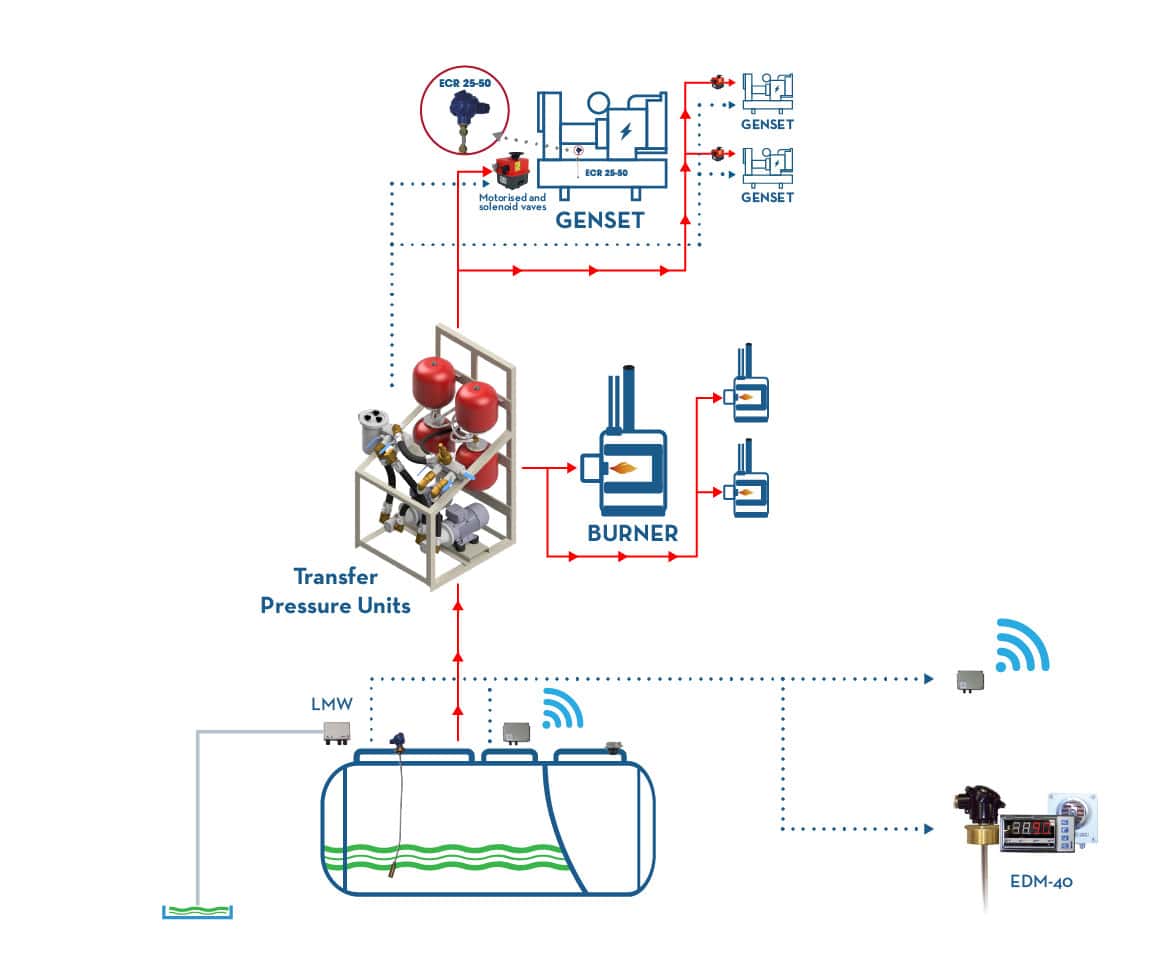

You will have the possibility to connect by Modbus and/or to Inpro Cloud

MODULARITY

You will have different modules with different functions that you can add depending on your requirements

VERSATILITY

The equipment has the possibility to supply different range of flow and management different languages

SUSTAINABILITY

Important reduction of Nº of components. Tha same control box for different types of equipment only with the change of the firmware

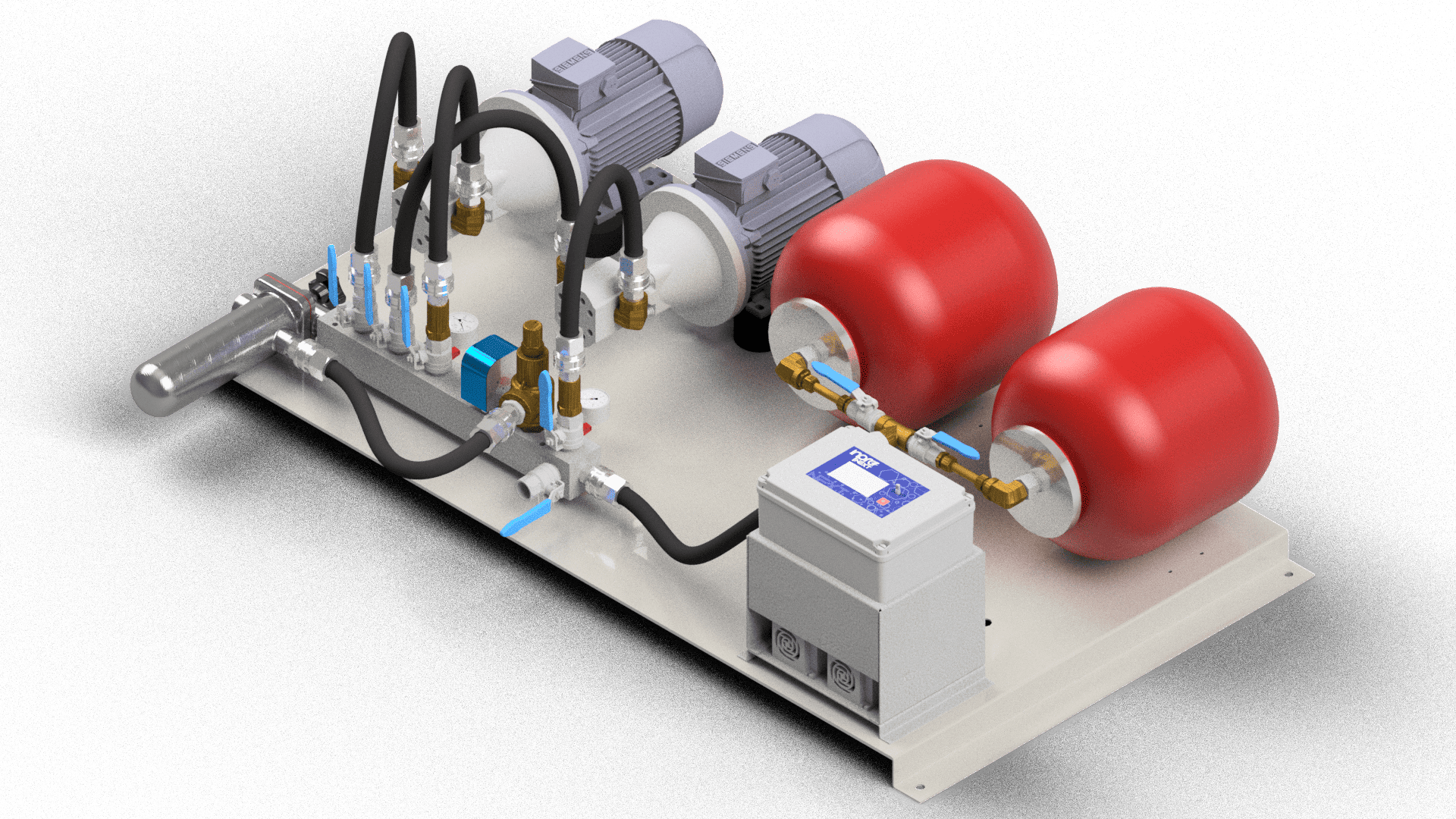

NEXT Units

They are our usual products but renewed and with new technical features. All NEXT units include the ControlBox.

Technical features of the Inpro NEXT units

-

Modular equipment so that communication modules can be integrated.

-

It will be possible to integrate equipment such as level probes to view statistics.

-

Extra connectivity possibility.

-

More versatile equipment.

Technical features of the ControlBox

NEXT products include the ControlBox which has the following properties:

-

New Display screen: Display and interactive screen with option to select in different languages. Currently available in English, Spanish, French, German and Polish.

-

3 expansion slots for additional functions

The ControlBox has a modular architecture that will allow through its expansion modules:

SignalHub module: integration of measurement and control sensors and their visualisation in the ControlBox integrated in the racking system. No need to purchase an EDM cabinet.

Data transmission through the ComHub module, which will allow the visualisation of all the data handled by the ControlBox through InproCloud.

The launch of the Inpro NEXT generation will start with the GPNext product in September 2024.

The NEXT units are provided with programmable Variable Frequency Drives (VFD) that allow:

With the following extras:

✔️Covering different flow ranges according to requirements.

✔️ Acceleration and braking ramps that allow:

- Smoother operation avoiding power surges, water hammer, pressure surges, etc.

- Decreases noise and vibrations in these transitions

- Increases life of hydraulic and electrical components

- Electricity consumption is reduced

ComHub Communication Module

Once the data has been received on the InproCloud platform via the “ComHub” Communication Module, it can be processed by the user:

Inpro NEXT = Sustainability

Units that have more flexibility to meet different requirements.

They are 100% compatible with hydrogenated vegetable oil (HVO).

Inpro NEXT products are more sustainable by reducing environmental impact.

This new generation has less equipment. And these teams are more versatile.

ControlBox detail

Learn more about our new Inpro NEXT units for energy solutions:

If you have any questions or need more details about our Inpro NEXT products, you can contact us using the following form. We will be happy to help you.