Safety and reliability in the transfer of fuel for data centres

In a data centre, where power availability must be absolute, every component of the backup system must respond with total reliability. When it comes to powering emergency generators with diesel or HVO, the choice of transfer system makes the difference between continuity and failure.

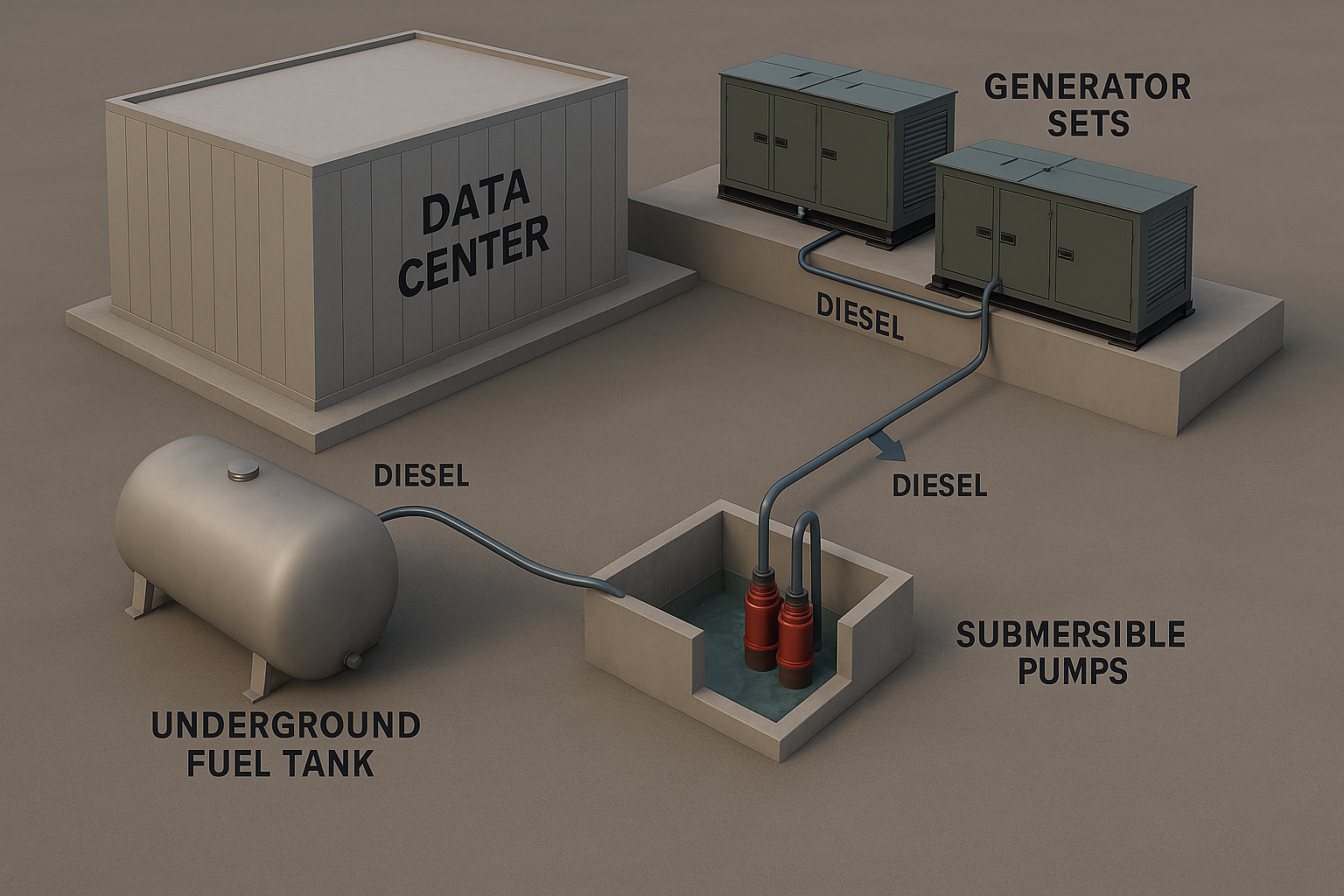

Submersible pumps vs Pressure Units in a data centre

What are submersible pumps?

Submersible pumps are commonly used to transfer diesel from main tanks to day tanks. They are generally suitable for use in small installations, with easy access to the tank and basic safety or automation requirements.

Main limitations:

-

High sensitivity to fluid and suction air quality.

-

Requires physical access to the tank in case of failure.

-

Less easy to implement redundancy or intelligent control.

-

More suitable for low criticality environments.

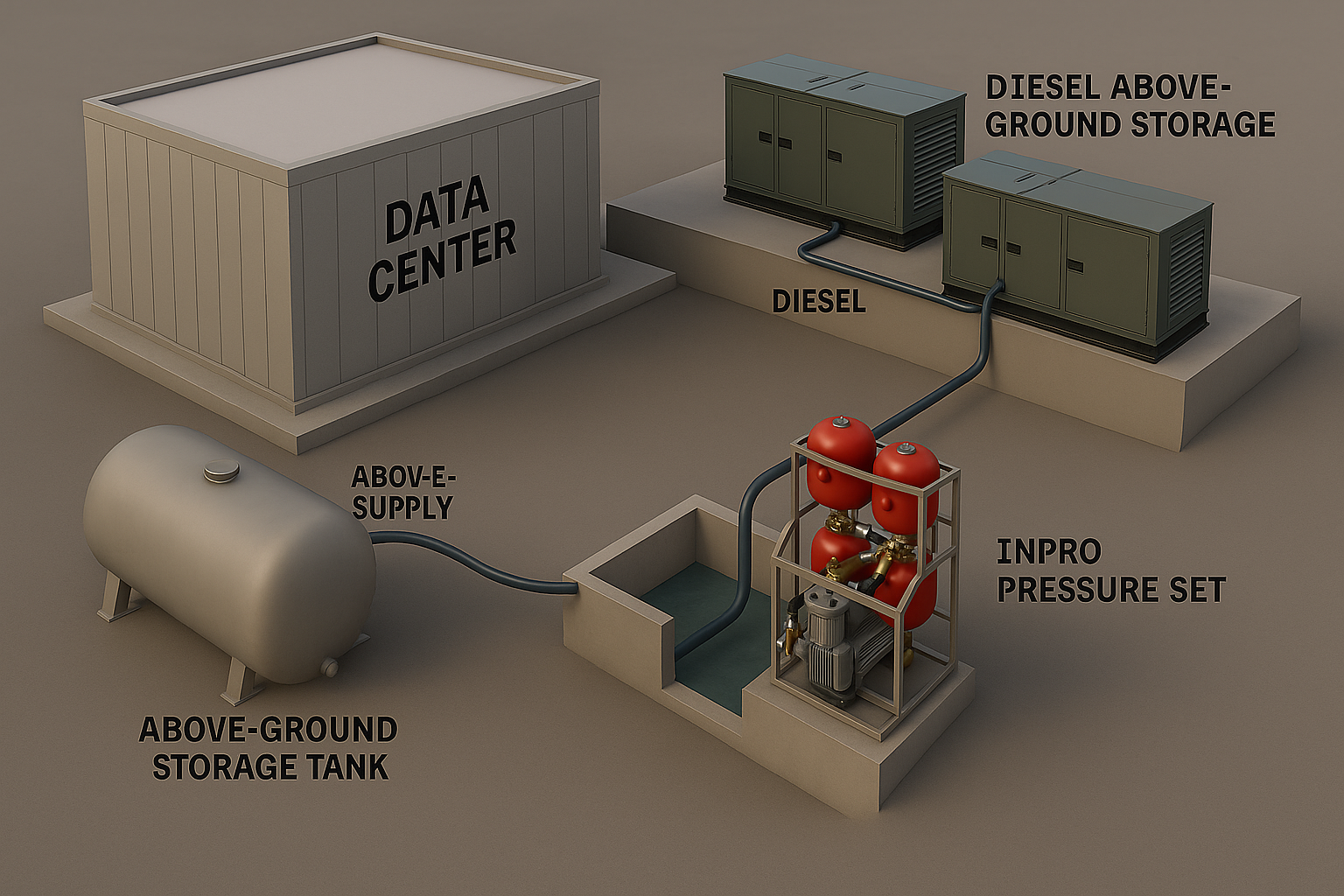

INPRO Pressure Units (GP)

-

Used to transfer liquid fuel such as diesel or HVO from a main tank to different consumption points through the pressurisation of a line.

-

For the supply of machinery requiring these fuels, such as generators (generator sets) or burners for boilers in buildings.

-

It does not require direct access to the interior of the tanks.

-

Various sizes and configurations of equipment are available.

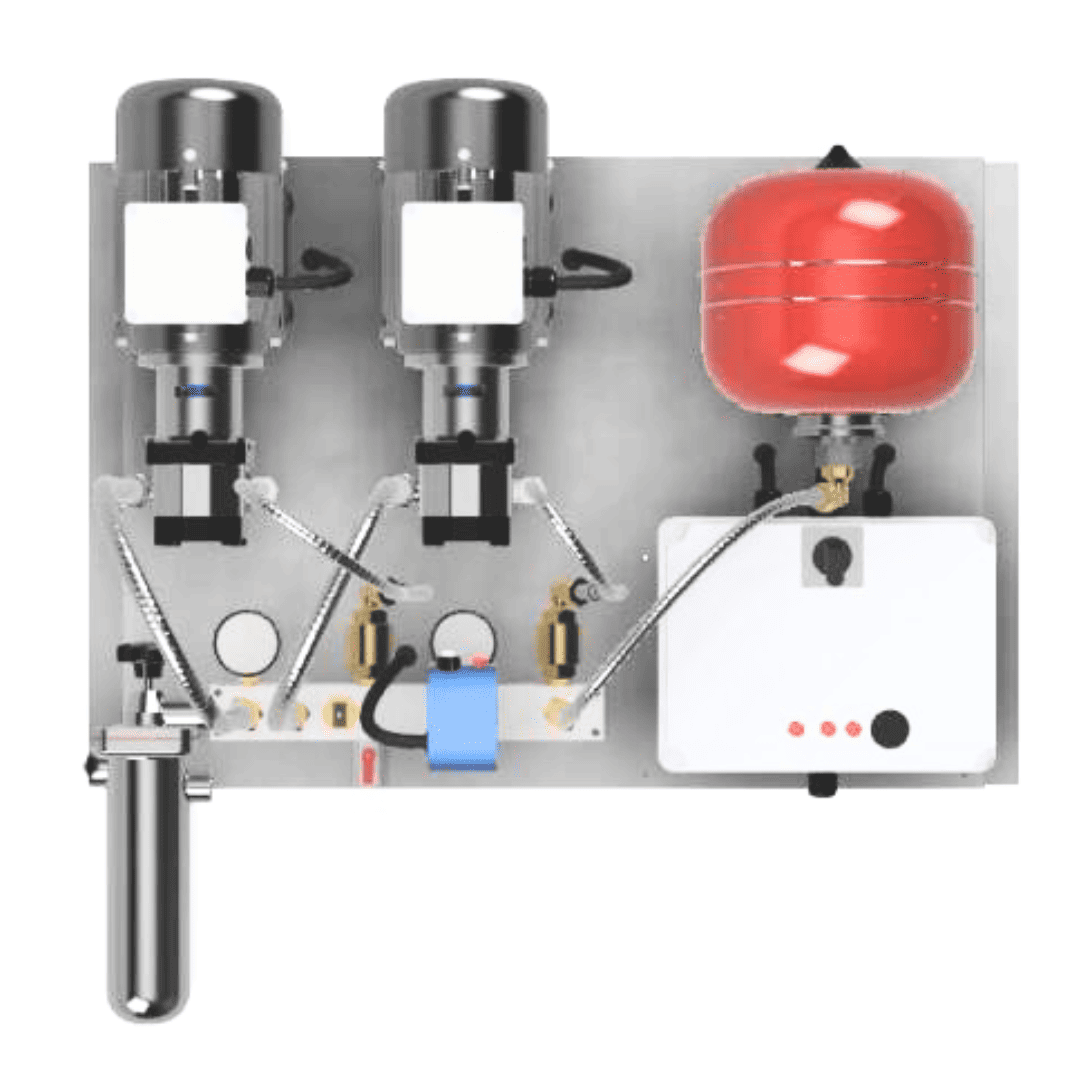

Key benefits of GP Pressure Units

-

There are various sizes and configurations of equipment in which you can vary the flow rate that the equipment can handle (from 30l/h to 12,000 l/h) and the maximum pressure at which they can work.

-

Total accessibility for maintenance without interrupting supply or emptying tanks.

-

Advanced safety: motorised valves, level control, automatic return in case of overfilling, leakage sensors.

-

High energy efficiency: all the motor energy is used for useful transfer (no losses).

-

Integral automation: PLC control with touch panel, ModBus communication, real-time alarm display.

-

SAFA preventive filtering and polishing system: eliminates water and particles, avoiding bacterial proliferation and obstructions in the generators.

-

Real redundancy: completely independent duplicated lines that guarantee continuous operation even in case of failure.

IDEAL APPLICATION OF EACH EQUIPMENT

Submersible pumps

They are a common solution for small or low requirement installations, where access to the tank is easy and a high level of automation or security is not required. They are mainly used when:

-

The system is simple and does not require intelligent control.

-

The installation conditions allow easy access to the tank.

-

No redundancy or remote control is required.

Pressure Units

Versatility and reliability for any installation. They are suitable for both small installations and large critical infrastructures, as they are available in a wide range of models and configurations.

Models and capacities available:

-

Flow rates from 30 l/h to 12,000 l/h.

-

Pressure adjustable according to project requirements.

-

Available in single or twin (redundant) version for maximum reliability.

-

Intelligent control with PLC and possibility of integration with BMS systems.

-

Single-phase or three-phase power supply options.

GP Pressure Units: SAFA preventive fuel polishing system

Actually, the presence of biodiesel blends in diesel, causes the possible proliferation of bacterial colonies, fungi or yeasts by chemical change of the fuel and the presence of water, mainly related to the increase in condensation inside the tanks. These colonies of bacteria cause clogging of filters.

The installation of fuel polishing systems with filters for capturing water and solid particles, eliminates the possibility of proliferation of bacteria, since you need water as an element to develop, feeding on hydrocarbon.

On the other hand, periodic recirculation homogenizes the fuel and prevents mixture stratification and oxidation.

In a data centre, there is no margin for error

The integration of the fuel filtering and polishing systems with the racking system is providing a more robust and secure solution in projects to ensure operational readiness. More and more data centres in service are implementing these preventive filtering systems.

Submersible pumps may be a viable option for simple environments, but when it comes to real energy security and operational continuity, only a solution based on Inpro’s advanced Pressure Units and systems guarantees the peace of mind that critical installations demand.

For more information

For more information about our products, services and projects, please send an e-mail to info@inprord.com or fill in the following form: