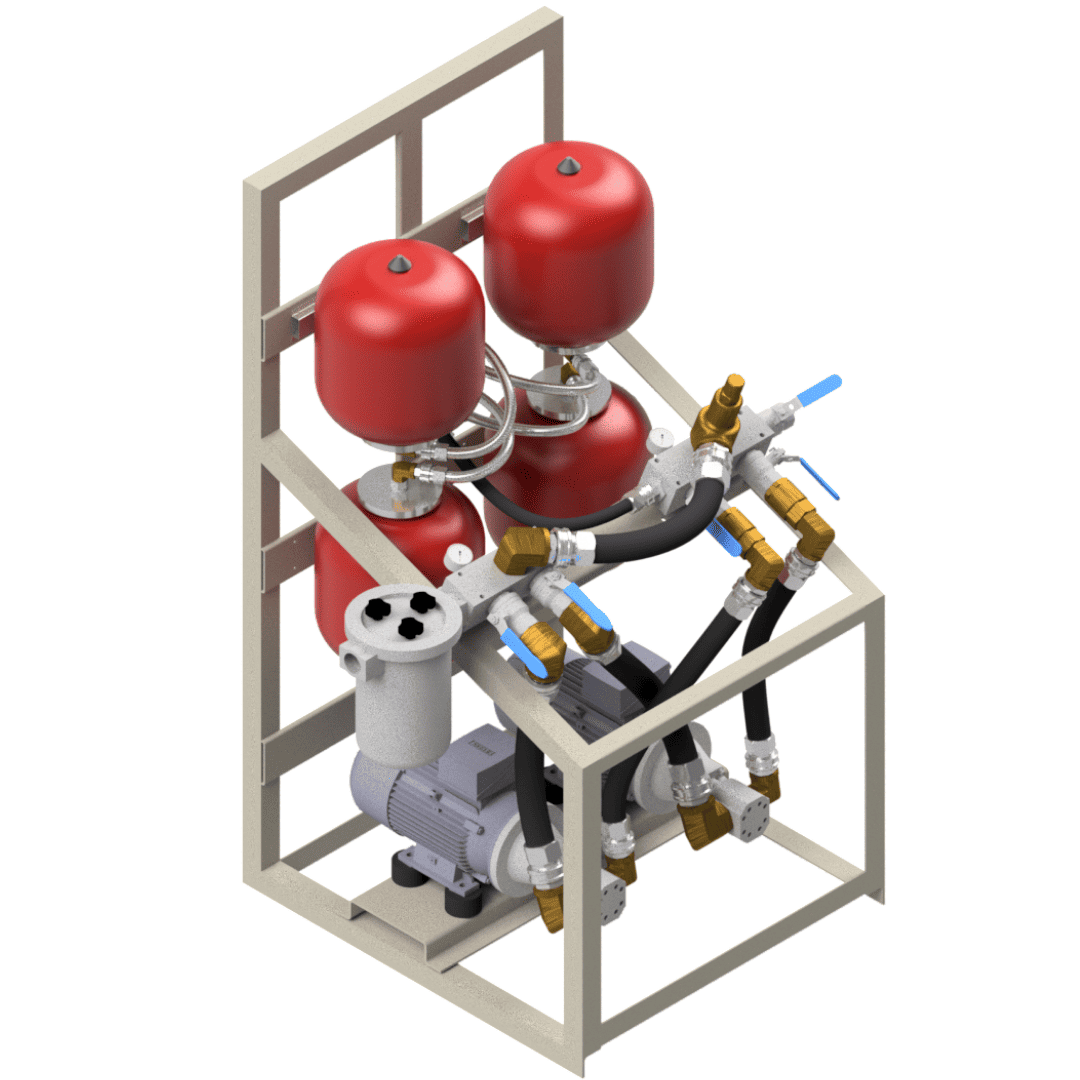

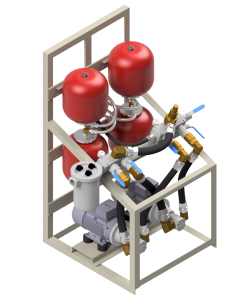

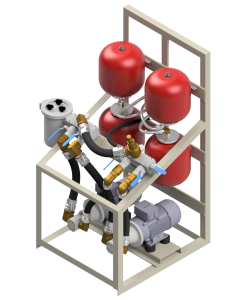

OIL TRANSFER PRESSURE UNITS- HIGH FLOW SYSTEMS- From 2,000 l/h to 12,000l/h

1 pump- 2 pumps

Inpro pressure units are equipment used to transfer liquid fuel such as diesel or HVO from a main tank to different consumption points through the pressurization of a line, for the supply of machinery that requires these fuels, such as generators (power generators) or burners for boilers in buildings.

.

There are several sizes and configurations of equipment, in which the flow rate that can control the equipment can vary (from 30l/h to 12,000 l/h), the maximum pressure at which they can work, with the possibility of redundancy in some components, and other parameters such as the type of power supply.

.

It can be Normal or Twin equipment that duplicates critical components to increase reliability.

- Gas threaded flange DIN-2576 PN-1

- For high flow rates from 2,200 l/h to 12,000 l/h.

- Perfect for critical facilities such as airports, hospitals or Data Centers.

- 2 pumps skid possibility that duplicates critical components to increase reliability.

- Includes an infrared leak detection system.

- 6 signals output for reporting status and alarms to central BMS

Application area example

Small units (from 30l/h to 1,500l/h) can be used for:

- The supply of boilers in single-family houses.

- Community of neighbors buildings

- Small installations.

And large units (from 2,000l/h to 12,000l/h) can be applied in:

- Large buildings requiring 24h/7 electricity

- Data Centers

- Hospitals

- Airports

- Malls…

Applications & Specific Features

- Multiple burner, appliances or service tanks supplied with one GP pressure unit.

- Appliances installed at different heights.

- Modulating burners when using the Inpro Oil Burner Inlet Assembly (see Datasheet).

- Oil Supply installation using ‘dead leg’ pipework. GP unit does not need external controls.

- GP units operate on an internal pressure switch only pumping fuel when required.

- Pressure regulators may be required at oil inlet to burners/appliances.

- Limited suction lift may require GP unit to be sited near the oil tank.

Accessories and Adaptations

- Free voltage relay output to control from centralised Building Management System, in kit 3, 4 or 6 signals (2-thermal, motors 1 or 2 ON, low pressure and Leak safety ON).

- GSM alarm system by SMS messages, or connection to modem.

- Adaptation of Pressure Group for high pressure, working conditions of up to 6 Kg/cm2

- Leak collector trays with infrared detectors (standard in GP-800 and GP-1500).

- Modifications to adapt to specifically regulated environments with tropicalised equipment or ATEX.

- Solenoid valve

Technical Features

| MODEL | GP-2200 NT GP-2200 GE |

GP-3200 NT GP-3200 GE |

GP-4200 NT GP-4200 GE |

GP-6500 NT GP-6500 GE |

GP-8500 NT GP-8500 GE |

GP-12000 NT GP-12000 GE |

|

|---|---|---|---|---|---|---|---|

| FLOW | l/h | 2200 | 3200 | 4200 | 6500 | 8500 | 12000 |

| CONNECTION TO THE HYDRAULIC CIRCUIT (Ø THREAD / Ø mm) |

SUCTION | 1” F | 1” 1/2 F | 1” 1/2 F | 2” F | 2” F | 2” F |

| DRIVE | 3/4” F | 1” F | 1” 1/4 F | 1” 1/2 F | 1” 1/2 F | 2” F | |

| POWER SUPPLY | VOLTS | 230/400 tri-phase |

230/400 tri-phase |

230/400 tri-phase |

230/400 tri-phase |

230/400 tri-phase |

230/400 tri-phase |

| MOTOR POWER | C.V. | 2 | 2 | 3 | 4 | 4 | 5,5 |

| KW | 1,5 | 1,5 | 2,2 | 3 | 3 | 4 | |

| MAX. PRESSURE | kg/cm2 | 3,5 | 3,5 | 3,5 | 3,5 | 4 | 4 |

| SAFETY VALVE OPENS AT: | kg/cm2 | 4,5 | 4,5 | 4,5 | 4,5 | 4,5 | 4,5 |

| PIPPING SUCT/PRES | 1½” / 1” | 2” / 1¼” | 2½” / 1½” | 2½” / 1½” | 3” / 2” | 3” / 2½” | |

| MOTOR PROTECTION | IP | 55 | 55 | 55 | 55 | 55 | 55 |

– Sound Level: 60 dB (A)

GP-GC GP GC GPGC

3D Pictures