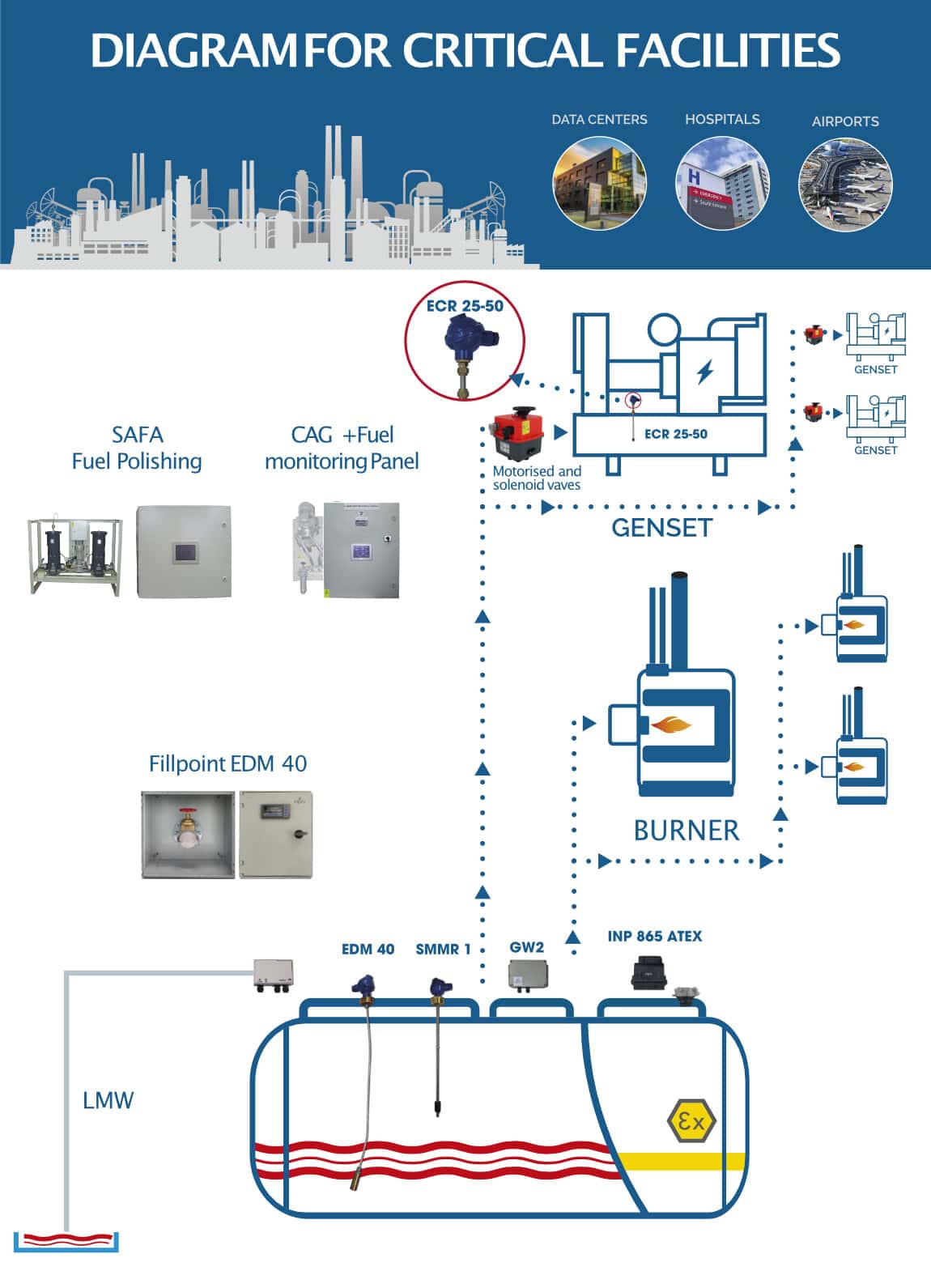

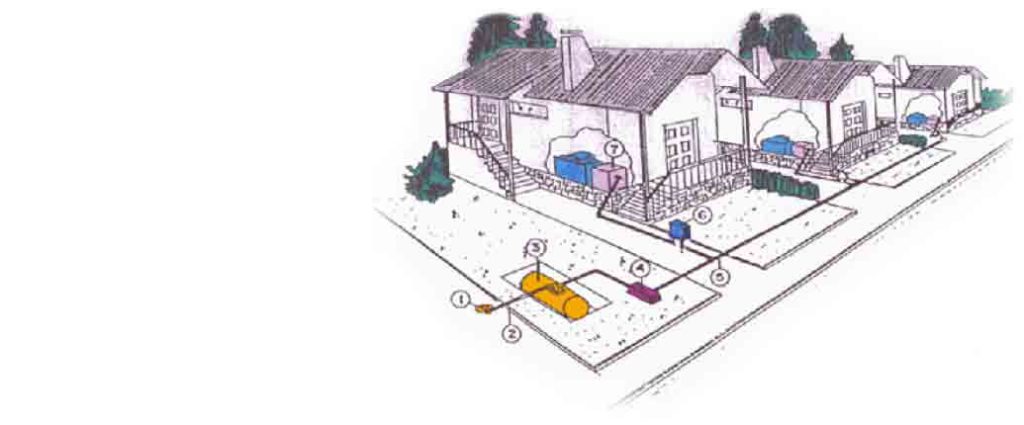

The next project required automated supply of JET-A1 aircraft fuel for testing engines in bench.

In this process, the unloading process of the tanker to the main tank had to be monitored and managed, with the help of an unloading pump.

But the main challenge of the project were the operating supply requirements in aircraft engines. The most important condition for a proper operation of the bench, located 100 meters away and with a height difference of 15 meters, was supplying fuel at constant pressure, flow and temperature. A 3000 L/h flow with a constant pressure of 8 bars regardless of the number of operating engines, maintaining stable flow and pressure at all times.

Due to the characteristics of the fuel, the installation had to comply with Area-1 classification standards, so all electric elements had to comply with the requirements to work in areas at high risk of explosions, in compliance with current regulations. Moreover, shut-off valves were installed every 20 meters along the perimeter of the pipe for safety reasons.

Solution adopted by INPRO

Pump Systems

• Tanker unloading system:

Consisting of a 20,000 L/h motor pump with a three-phase motor III x 400Vca – 50 Hz of 3 KW and P55 – EExeIIBT4 protection, by-pass, gearbox at 430 r.p.m.; filter and retention valve. Everything was mounted on a steel frame.

• Pump supply system:

Supply to the engine bench is done by a pump system consisting of two explosion-proof motor pumps with three-phase motor III x 400Vca – 50Hz at 2.2 KW and EExeIIBT4 – IP55 protection capable of supplying 4,500 L/h each at a 7.5 bar pressure. These motor pumps were mounted on a steel frame with spill tray and detection by capacitance probe. The unit has: Filter, by-pass, retention valves, minimum pressure switch to block the unit and avoid no-load operation, manometer, safety valve with exhaust lines and shut-off valves.

On the return line, a regulation and stabilization valve is installed, adapted to the operating conditions.

Control Panels

The control panel manages both the unloading system of the tanker and the pump system for the fuel ring; this is installed outside the danger zone.

Operations:

• Tanker unloading system:

– The system is operated with a go – stop switch (local and remote)

– As overfilling protection, a maximum level pump stop was planned as well as the required thermal protection in the engine.

• Pump system – Ring system:

– A rotating commuter serves to select the operation mode of the system. (Off – Automatic – Manual Pump 1 – Manual Pump 2)

– In Automatic mode the pumps alternate, so each pump works for 10 minutes. If the thermal protection of one of the engines is triggered, the other motor pump starts operating automatically.

– In Manual mode, Pump 1-2, this does not happen.

– If pressure drops below the established value in the minimum pressure switch regulator for any reason, the system gets locked to protect the pumps from no-load operation. Pumps keep working during those 5 seconds, in case the issue was an occasional excessive consumption; if pressure does not go up, the unit stops and must be manually reassembled.

– The pump system is fastened with the testing benches, so the pumping process only occurs if there are operating reactors.

– System interruption due to spillage is planned for (intrinsic safety), so if any leak is detected on the tray, the pump system stops.

Elements of the installation supplied by INPRO

LEVEL SWITCH

SMMR level switches perform the operations required for the filling process and the tank overfilling alarms and protocols. Custom manufacture based on actual needs.

• Probes manufactured from different materials to work with fluids such as gas oil, oil, water, milk, etc.

• Probe with sealed head, can be fastened with 2’’, 11/2’’ or 1’’ nuts, mounted with aluminum or standardized flange.

• For controlling pumps, solenoid valves, alarms, etc…

• Control box with relays and power supply.

TRANSFER PUMP

Pump with self-adjusting blades, with positive movement and constant flow. Silent, robust and high-performance. Particularly recommended for transfer of all kinds of liquid -as long as they are not abrasive nor contain suspended solid particles.

• Blade adjustment is due to three variables. Centrifugal force, fluid pressure and push rods, so losses and turbulence are greatly decreased.

• Adjustable safety valve included in pump body.

• Pump body in cast or stainless steel, based on needs.

• Bench from gray cast iron.

• Three-phase engine with Atex certificate.

• Possibility of 2 rotation directions by placing an inverter.

• The power of the associated motor prevents possible problems at launch with low temperature fuel.

Pump unit “INPRO” FP GET

Compact pump unit for gas oil pumping. Contains all the elements required for the proper operation of motor pumps in one bench.

• Gear electric pumps with three-phase or mono-phase supply.

• Motor protection IP-55

• System to interrupt no-load operation in case of lack of fuel

• Alternative electronic control management system v

• Vacumeter

• Aluminum filter, Retention valves.

• Safety valve with exhaust line.

Kerosene Unit

• Digital output for incidence control from central position in kit 3, 4 and 6 signals (2-thermal, 2-motors OK, low pressure and spillage).

• Launch scheduling kit due to lack of current.

• GSM alarm system via SMS messages or modem connection.

• Line pressure switch for low pressure signal.

• Modifications for adapting tropicalized and ATEX units.

• Spill collector trays with infrared detectors.

• There are supply system versions for other fluids such as light fuel, methanol, gasoline, etc…

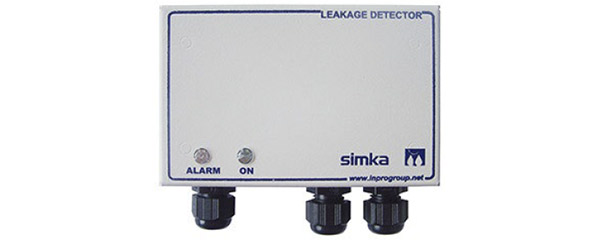

COLLECTOR TRAY WITH SPILLAGE DETECTOR

Placing collector trays under certain elements of the installation is recommended. Particularly, equipment that could leak due to its characteristics or during maintenance tasks. Placing a spillage detector for the tray gives the possibility of creating protocols.

• Furnace-painted plate tray with the appropriate size for each circumstance.

• Spillage detector in the control panel and detection probe. Infrared optical sensor for oil and water, conductivity sensor for water or both, mounted on the same probe.

• Standard 1.5 m probe.

• The control unit of the detector is mounted in a box with impact-resistant plastic cover. The control unit contains two voltage free relays, one for commuting and the other one usually open.

PRESSURE REGULATOR VALVE

Constant pressure and flow regulator valve according to consumption variations

• For gas oil, lubricant and hydraulic oils.

• Maximum temperature of the fluid: 250ºC.

• Hydraulic cast iron. Piston, needle and tempered steel spring.